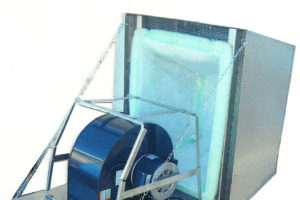

This blower system was designed for large (20,000 gallon+) liquid storage tanks. The HAV utilizes the same-patented technology as the PAS System, but does not incorporate ultraviolet light. It operates on the principal of eliminating the dew point within the head-space of the tank, not allowing yeast; mold or any other inoculates to take hold. The HAV blower forces air through a specially designed HEPA Filter, filtering air to .3 microns and entering the tank at a volume of 500 CFM. This air circulates through the head-space and exits through a specialty vent that does not restrict the exit airflow. Like the PAS System, due to the nature of the filters and design, new gasket material is in place every time you change out the filters. This maintains a very tight seal around all the components to eliminate all air bypasses.

The Pre-Filter will trap particulates down to 10 microns, much smaller then most electrostatic filters, taking the boulders out of the air and reducing the build up load on the HEPA. This Pre-Filter is over 1500 sq. inches.

Like the PAS System, all blower contaminants are trapped in the HEPA. All blower motors are dirty components and throw off particulates from the windings, bearings and armatures that can become part of your ingredient if not removed. The HAV will not allow anything but the cleanest, purest air possible to enter the tank head-space.

Normal filter change out is once a year, although changing out the Pre-Filter more frequently can extend the HEPA filter life. Made up of all stainless steel construction, this HAV system will provide many years of service.